"A warm composite with the natural charm of exotic wood "

A warm composite that enhances your outdoor spaces

- Warm appearance and realistic graining imitate natural wood

- Slightly brushed matt finish for a pleasant feel

- Designed in co-extruded composite, combining wood fibre and high-density polyethylene

- High stability and resistance to weathering, fungi and wear and tear

- Perfect for low-maintenance terraces with a timeless, long-lasting look.

Wood ageing

Nekko, whether brown or grey, ages with great stability thanks to its co-extruded composite design. Unlike natural wood, it greys very little , if at all , over time and retains its original colour for a long time. Its protective outer layer makes it UV, weather and stain resistant, This prevents any discolouration or major alteration to its appearance. Minimal maintenance is required to preserve its aesthetic appearance.

Nekko Brown is made from wood fibre and high-density polyethylene, a unique blend offering a robust, durable material that is perfectly suited to the demands of outdoor environments.

Performance and reliability

Thanks to its co-extruded protective layer, Nekko Brown is UV, weather, stain and scratch resistant, while retaining its dimensional stability and natural appearance over the long term.

Warm, durable aesthetics

With its warm brown appearance and realistic grain, Nekko Brown preserves its original charm without greying or fading, It blends in harmoniously with timeless, welcoming exterior designs.

Treatment process

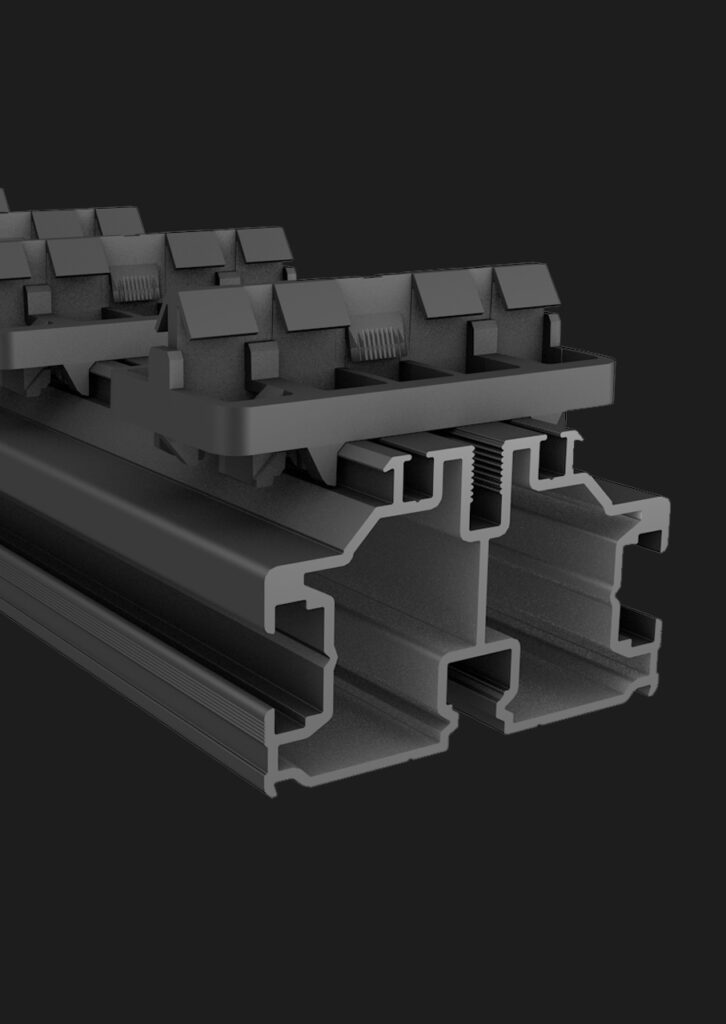

Nekko is a co-extruded composite material, made froma blend of wood fibres and high-density and high-density polyethylene (HDPE), reinforced with additives. This process combines the advantages of wood and plastic, offering both natural aesthetics and enhanced durability.

Preparation of the raw materials:

Wood fibres (approximately 55% for the core) are mixed with high density high-density polyethylene (HDPE) and specific additives (UV stabilisers, colour pigments, binding agents), colour pigments, binding agents ).

Core extrusion:

The mixture is heated and extruded to form the core of the blades, guaranteeing a stable and homogeneous structure.

Co-extrusion of the protective layer:

A thin outer layer (approximately 45% wood and 40% HDPE ) is co-extruded onto the surface. This protective coating enhances resistance to stains, scratches, UV and weathering.

Cooling and finishing:

Extruded planks are cooled and calibrated to the desired dimensions. A brushed or matt finish is added for a pleasing look and feel.

Applying Kebony®

Kebony uses a patented modification process called furfurylation.

Furfurylation uses a biological liquid called furfuryl alcohol, derived from agricultural plant waste. Furfuryl alcohol is injected into the sapwood cells and, when combined with heat, bonds permanently, transforming softwood into hardwood. Although chemicals are used, the product is non-toxic, both during and after service.

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Case studies

Our deck boards are certified