" Innovative, durable bamboo that withstands the elements".

Bamboo with a modern, sustainable design

- Made from MOSO® bamboo a resource renewable

- Chocolate, dark brown

- Thermo-Density® heat treatment for a robust, attractive finish

- Increased resistance to weather, insects and moisture

- Perfect for modern, elegant outdoor projects, offering unrivalled durability and unique aesthetic appeal.

Wood ageing

MOSO® Bamboo X-treme® ages by developing a natural, elegant silver-grey patina when exposed to the elements and UV rays, similar to the ageing of many natural woods. Here are a few details:

Colourchange:

Initially, MOSO® Bamboo X-treme® has a dark brown colour due to the heat treatment. Over time , without maintenance, this colour will gradually fade to a uniform silver-grey.

Stability and durability maintained:

This colour change is purely aesthetic and does not affect the structural stability of the material.

Thanks to its high density and , it remains resistant to deformation, cracks and other impacts caused by external conditions.

Maintenance options :

To maintain its original dark brown colour, you can apply a suitable oil or UV protection once or twice a year.

If left untreated , natural ageing produces a homogenous grey finish, often prized for its contemporary appeal.

In a nutshell, MOSO® Bamboo X-treme® ages harmoniously and offers flexible options according to aesthetic preferences.

MOSO® Bamboo X-treme® is made from MOSO® bamboo, a fast-growing, renewable resource, responsibly cultivated to guarantee an ecological, high-performance material.

Exceptional natural robustness

Modern, timeless design

With its dark brown colour that can evolve into a refined silver-grey, MOSO® Bamboo X-treme® fits in perfectly with stylish outdoor design projects, combining durability and sophistication.

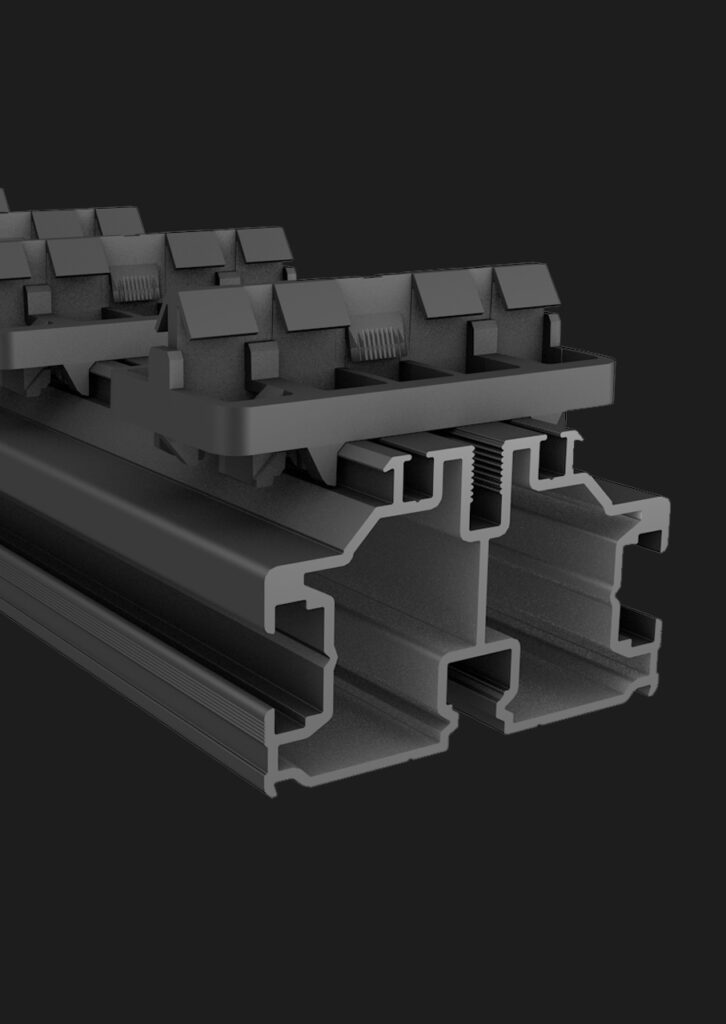

Treatment process

Applying Kebony®

Kebony uses a patented modification process called furfurylation.

Furfurylation uses a biological liquid called furfuryl alcohol, derived from agricultural plant waste. Furfuryl alcohol is injected into the sapwood cells and, when combined with heat, bonds permanently, transforming softwood into hardwood. Although chemicals are used, the product is non-toxic, both during and after service.

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Lorem ipsum dolor sit amet consectetur adipiscing elit dolor

Case studies

Our deck boards are certified