History of the company

Thermory, founded in Estonia in the late 1990s, is a world leader in thermally modified wood. Initially focused on sauna materials and flooring, the company expanded into decking and cladding in the 2000s, acquiring a strong international presence. A major milestone was reached in 2018 with the merger with Ha-Serv, making the company the world’s largest producer of thermally modified wood.

Thermory continued its growth by acquiring Siparila Oy in 2020, strengthening its Nordic presence. With production sites across Estonia, Finland and Belarus, Thermory remains dedicated to sustainability and innovation in wood solutions.

Thermory in a few figures

Thermory is currently the world’s largest manufacturer of thermally modified wood. The company exports to over 50 countries worldwide.

Thermory has 13 production facilities in Northern Europe, including 11 factories and 2 sawmills.

The Thermory Group processes 187,000 m³ of raw materials every year. Thanks to a conscientious sourcing policy, this wood comes from sustainably managed forests.

Products

Thermory’s ash is a thermally modified wood designed to deliver exceptional performance while retaining its natural beauty. Thanks to the thermal modification process, ash gains dimensional stability, durability and weather resistance, making it an environmentally friendly alternative to tropical hardwoods.

Main features of Thermory:

Increased durability: Thermal modification gives the wood a durability comparable to that of exotic hardwoods, making it ideal for outdoor applications such as decking and cladding.

Elegant Esthetics: Thermo ash features a rich dark brown hue with prominent grain patterns, perfect for high-end architectural and decorative projects.

Dimensionalstability: The thermal process considerably reduces the risk of warping, shrinkage or swelling due to humidity.

Sustainable sourcing: Ash wood is sourced from sustainably managed forests, in line with Thermory ‘ s commitment to environmental responsibility.

Thermory thermo spruce is a thermally modified spruce wood, designed to offer durability and performance in a wide range of applications. Thanks to the thermal modification process, spruce acquires enhanced properties that enable it to adapt to demanding environments while retaining its natural beauty.

Key features of Thermory Thermo spruce:

Improved durability: Heat treatment considerably increases the wood ‘s resistance to decay and the elements, making thermoepicea an excellent choice for exterior applications such as cladding and decking.

Light and versatile: spruce is naturally light, making it easy to work with and ideal for a variety of construction and design projects.

Beautiful esthetics: thermoformed spruce has a warm, golden hue after the thermal process, lending a natural, elegant look to any project.

Sustainable sourcing: The spruce used by Thermory is harvested from sustainably managed forests, which testifies to the company ‘ s commitment to environmental responsibility.

Why we chose Thermory ?

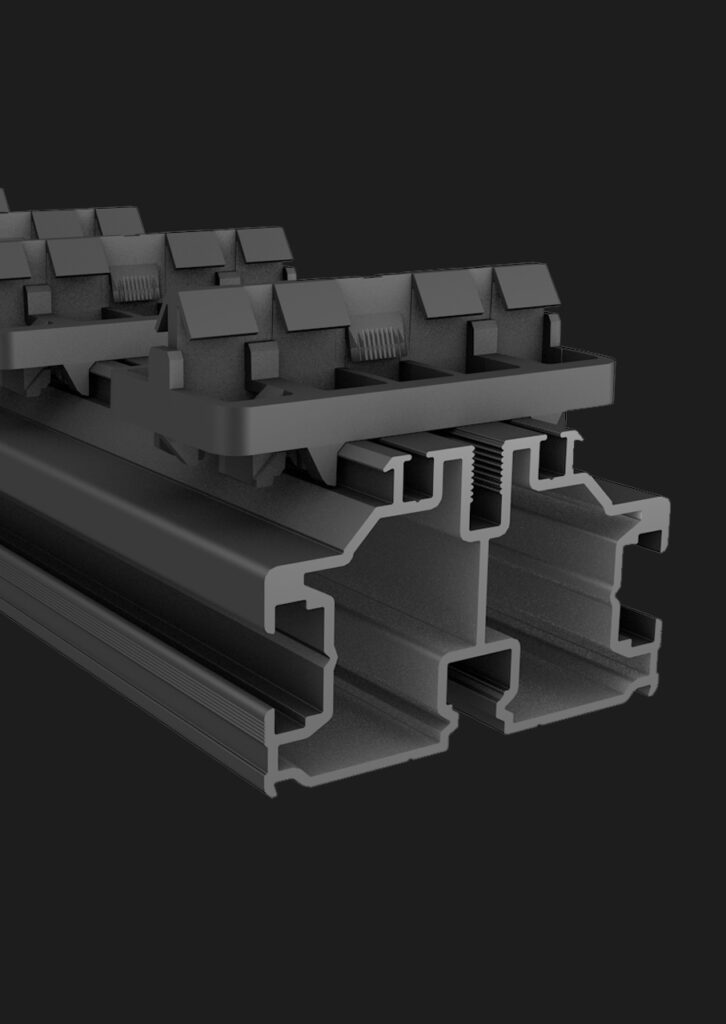

- Outstanding product quality Thermory is recognized worldwide for the exceptional quality of its thermally modified wood, which offers outstanding durability and dimensional stability. These attributes are essential to the success of Grad, such as the Grad® profile.

- Innovation and technical expertise Thermory was an early adopter of GIPI, technology at an early stage , enabling the grooves required for the Grad system. This level of innovation and technical mastery ensures perfect compatibility with Grad requirements.

- Reliability and production capacity With 13 production units and an impressive annual output , Thermory can supply large volumes while maintaining high quality standards. Grad thus benefits from a stable and reliable supply for its projects.

- Shared commitment to sustainable development Both companies share a philosophy of environmental responsibility. Thermory uses wood from sustainably managed forests, a perfect fit with Grad 's ecological values.

- This combination of quality, innovation reliability and shared values makes Thermory a reliable and valuable partner for Grad.

Thermory has been at the forefront of innovation in wood processing, becoming one of the first companies to invest in a GIPI machine to create the GRAD groove, a system that guarantees precision and ease of wood installation. To remain at the forefront of the industry, Thermory renewed this investment in 2021 with the acquisition of a second GIPI machine. This addition has enabled them to increase their production capacity and meet growing demand, reinforcing their position as a leader in thermally modified wood solutions.