Scroll down

Commitments

OUR PHILOSOPHY

INNOVATIVE

We aim to develop simple, sustainable, reliable and scalable solutions for our customers.

RESPONSIBLE

We select materials that meet our technical requirements and work primarily with suppliers that are committed to processes aimed at reducing their environmental impact.

SUSTAINABLE

INNOVATIVE

We aim to develop simple, sustainable, reliable and scalable solutions for our customers.

RESPONSIBLE

We select materials that meet our technical requirements and work primarily with suppliers that are committed to processes aimed at reducing their environmental impact.

SUSTAINABLE

We believe in the longevity and quality of our products such that they stand the test of time.

Our company fully embraces a vision

focused on sustainability

and environmental stewardship. We also attach

a lot of importance

to developing

and perfecting our system, by following

regulatory standards

to the letter.

Conscious that the future of our planet is at stake

and being played out right now,

our initiatives and developments

are put together with this in mind.

This is why our processes

and environmental impact

are under

constant evaluation so that we can continue

to improve our

practices and products at all times.

In particular, we have undertaken a series of measures

aimed at taking on

the environmental challenges of the moment,

including adopting sustainable

and eco-responsible

production methods at every stage

of the process,

from the selection of the materials

and suppliers onwards.

We make smart investments in innovative

solutions so that we can

provide a cutting-edge

system that will stay looking great for a long time

to come while

optimising the use of resources, minimising waste

and promoting circularity.

Our company fully embraces a vision focused on sustainability

and environmental stewardship. We also attach great importance

to developing and perfecting our system, by following the regulatory standards

to the letter.

Conscious that the future of our planet is at stake and being played out right now, our initiatives and developments are put together with this in mind.

This is why our processes and environmental impact

are under constant evaluation in order to continue improving our

practices and products at all times.

In particular, we have undertaken a series of measures aimed at taking on the environmental challenges of the moment, including adopting sustainable

and eco-responsible production methods at every stage of the process,

from the selection of the materials and suppliers onwards.

We make smart investments in innovative solutions so that we can

provide a cutting-edge system that stay looking good for a long time to some while optimising the use of resources, minimising waste

and promoting circularity.

Our mission

and sustainable high-quality technical fixing

solutions for private, public

and architectural applications with the goal of becoming

the leader on the market in France and abroad.

Develop innovative, uncomplicated and sustainable

high-quality technical fixing solutions for

private, public and architectural

applications with the goal of becoming

the leader on the market in France and

abroad.

We prioritise the quality of the products and services from studying the need

to providing support in the field (specialised drawing tool and design office

for bespoke solutions, responsiveness, dedicated customer service, assistance

with communication and sales, technical training and product

presentation, etc.). Our main goal is to establish lasting partnerships

by placing our customers at the centre of our concerns.

At Grad®, we think about the future. Sustainable decisions and strong partnerships

with our suppliers are essential in being able to surpass ourselves and offer our customers a high-end

experience over the long term.

As an industrial company, we face major challenges in our

approach to the design, procurement and production of our solutions.

We are constantly alert to the repercussions of our decisions and actions. This is why we have initiated a study of our carbon footprint to better

understand our current impact, with the aim of continually reducing it.

Consequently, we are more likely to select local partners

from France and Europe that are committed to an environmental approach, and materials

with a reduced impact on the environment, as well as eco-responsible and sustainable production

processes, wherever possible.

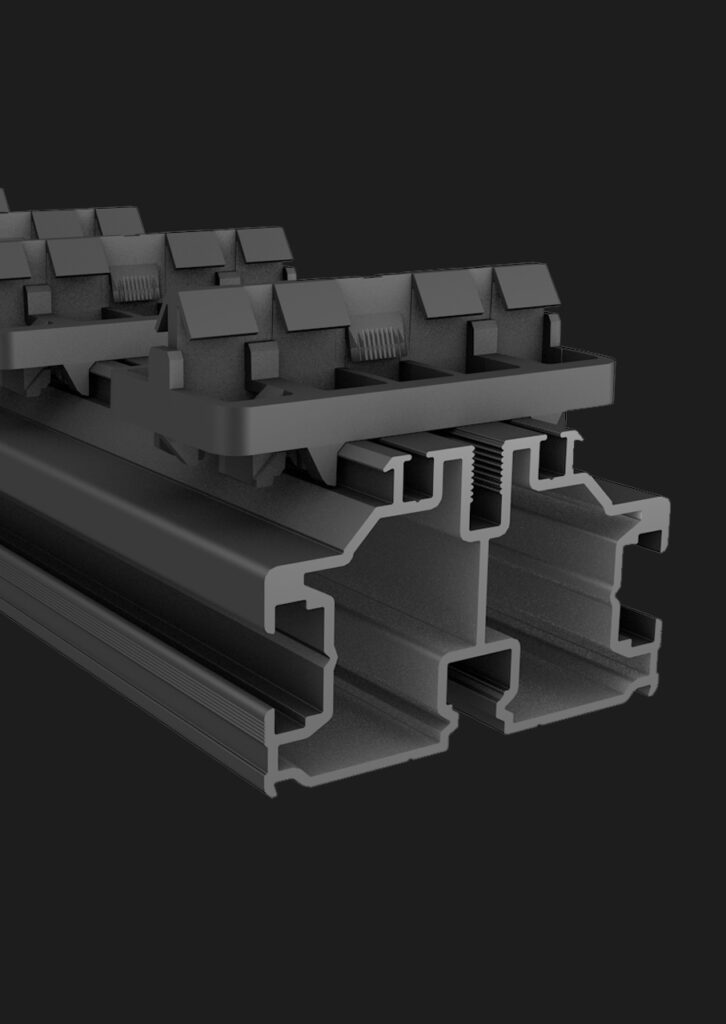

For example, the aluminium we use to manufacture our rails

is composed, on average, of 80% recycled material and is infinitely recyclable.

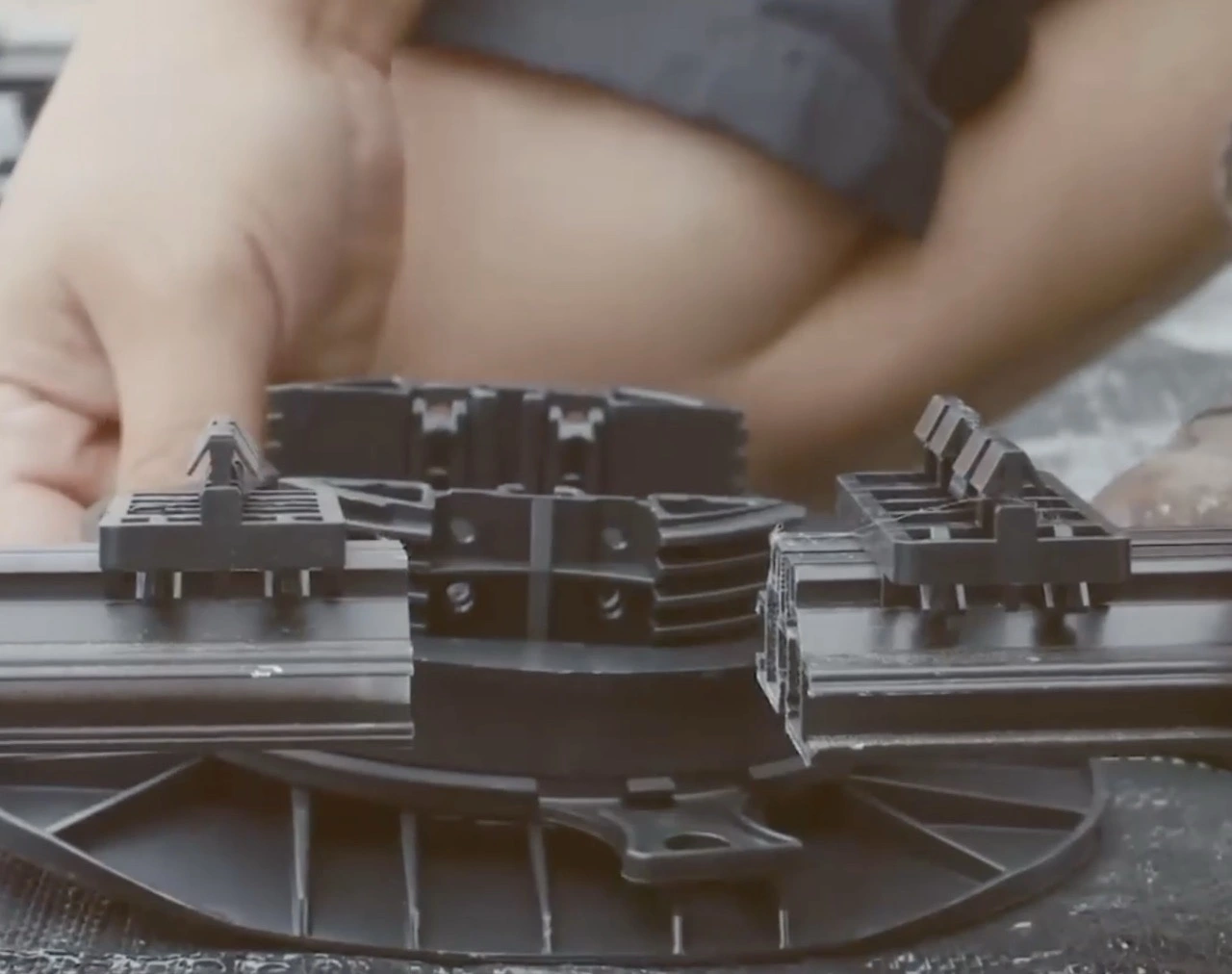

As for the polypropylene (PP) used to manufacture some of our accessories,

it contains 70% recycled materials.

We also decided to stop

using exotic wood types deemed too controversial from

an environmental and ethical standpoint.

In order to ensure the compliance of our system in France as well as internationally,

we strive to meet the applicable standards and regulations.

This is why the Grad® system is verified, tested and validated internally, in accordance with

an inspection plan, and externally with testing organisations and laboratories (e.g. FCBA)

to verify compliance with the standards applicable in France and internationally

(DTU 51.4 (decking), DTU 41.2 (cladding), Eurocodes, etc.).

Our company places human value at the heart of its mission. We are

deeply committed to the well-being of our employees, based on the premise that

every individual is a key contributor to our shared success.

We believe in the power of diversity of ideas and viewpoints. At Grad®,

every team member is important. We think, build and work together.

We make a point of ensuring the health and safety of all employees (specially designed and optimised workstations and equipment, safety-related training

courses, etc.).

We believe that a happy employee is a committed employee,

who will contribute to the growth and collective prosperity of our company.

A new building of interest

A new

building of interest

and craftsmen whenever possible.

As part of a group, whose core business is wood, Grad® has opted for interior partitions using wooden frames made by another brand of the Burger & Cie group, namely BOOA. As always, the reason for this is to keep our supply chains short and reduce our environmental impact.

At the same time, our business generates wood waste, which is reused for heating

our current premises. This heating method will be retained in our new unit.

about 561 MWh per year, which covers almost half of our

annual consumption in production.

What’s more, to minimise the use of artificial lighting,

natural light will be allowed in as much as possible by integrating glass walls

along the entire length of the building along with saw tooth rooflights.

In order to minimise energy losses, we are looking

to recover the heat coming from the cooling circuits.

about 561 MWh per year, which covers almost half of our

annual consumption in production.

What’s more, to minimise the use of artificial lighting,

natural light will be allowed in as much as possible by integrating glass walls

along the entire length of the building along with saw tooth rooflights.

In order to minimise energy losses, we are looking

to recover the heat coming from the cooling circuits.

With our future production flows and organisation,

we will be able to reduce the use of loading equipment

and temporary packaging.

By delivering our polymers in tankers and storing them

in silos, we will eliminate transport packaging.

In addition to the investments related to the building itself,

Grad® will be equipped with high-tech production tools

that can be used to reduce manufacturing times, and

the energy consumption times as a result. With our production flows and organisation, we will be able to reduce the use of loading equipment and temporary packaging.

With our future production flows and organisation,

we will be able to reduce the use of loading equipment

and temporary packaging.

By delivering our polymers in tankers and storing them in silos,

we will eliminate transport packaging.

In addition to the investments related to the building itself,

Grad® will be equipped with high-tech production tools

that can be used to reduce manufacturing times, and the energy consumption times as a result. With our production flows and

organisation, we will be able to reduce the use of loading equipment

and temporary packaging.

Our company is fully committed to an ambitious process

from the environmental and economic point of view

based on technical know-how and

respect for human values.

Our company is fully committed to an ambitious process

from the environmental and economic point of view

based on technical know-how and

respect for human values.